Services

Custom-made production

Are you looking for a custom-made solution? We can produce any straight knife from the thickness of 2 mm to the length of 4500 mm from tool and structural steel. We also supply all parts and accessories for machines of various world brands.

We have been engaged in custom-made production since 1934 and today we provide it to customers all over the world. We have the entire process in-house: from 3D scanner measurement and drawing documentation, through complete production and hardening to marking and packaging. We use advanced 3D technologies, carousels, balancers, hardening equipment and a wide range of large milling centers and grinders.

How to inquire about custom-made production

- Send us a drawing, video or photo with basic measurements or a sample of the required part.

- Describe to us how it is used (e.g. that it is intended for a specific type of wood).

- Finally, please indicate the required quantity.

- Our sales team, in cooperation with technicians, will assess the request and send you a quote.

For more complex inquiries, where there is no sample or drawing documentation, we can come to you and measure the required part or unit, ourselves on the spot. - If it is within our technical capabilities, we will print the designed part from several segments on a 3D printer, connect the segments and test dimensional compatibility.

Overhaul of parts and units

Do you have a worn or damaged part or unit? Find out if it could be overhauled. Overhauled products are an economical solution and have the same service life as new parts and units.

What we rebuild:

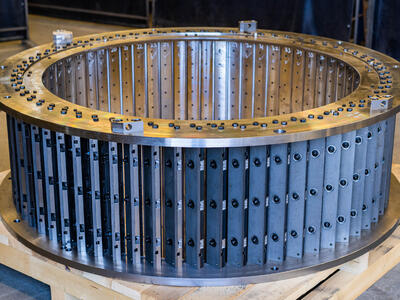

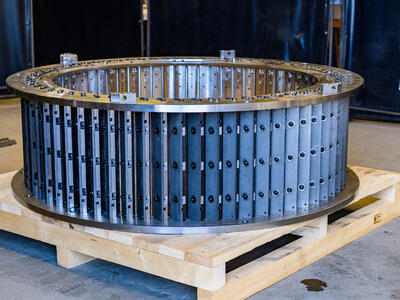

- Rotors and knife rings for flaker machines Pallmann, Globus, Maier, Bruks-Klockner and Leonhardt,

- rotors and grinding tracks for dry and wet mills of the Pallmann, Globus, Maier and Leonhardt brands,

- rotors for chippers,

- chipper feed rollers,

- debarker knives for OSB lines.

How to request an overhaul service

- Send us a drawing, video or photo with basic measurements.

- Enter the required quantity in the inquiry.

- Our sales person will work with technicians to assess the request and send you a quote.

- We will agree on the framework offer together.

- Finally, send us a part or a unit so that we can assess its degree of wear or damage in detail. If the framework offer does not require modification, we will finally confirm it.

Do you want to use custom production or overhaul?

Contact us, we will get in touch with you.